|

So, you’ve decided to live the dream and restore a classic car or are, at the very least, tempted by the idea of it. Great! But first things first- you need to make some decisions. Like any big project, and life in general, you need a plan. Getting organised and planning ahead is essential for restoration success. It doesn’t matter if you’re doing all the work, some of the work or even none of the (physical) work- you need to get it clear in your head what you want from the moment you start planning the project (ideally before you’ve even bought the car) if you want to end up with the ride of your dreams rather than the resto project from hell. 1) Choose your AestheticFirst of all, what style, concept or theme are you going for? For example, do you want something:

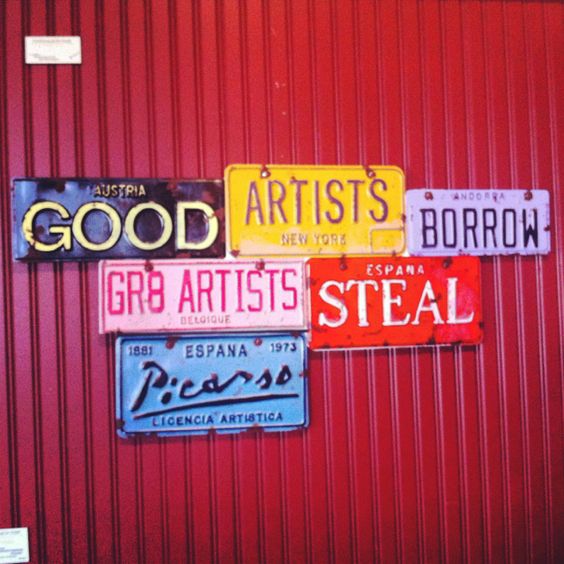

Look at recent trends for ideas- go to car shows, buy magazines (or not-so sneakily flick through them in the shop) check out blogs and websites focused on your car scene. Ask other people for their opinions too, using a good mix of those experienced with your type of car and laypeople who wouldn't know an air-cooled from a water-cooled. Above all talk to people that you know will give you their unfiltered, honest and informed opinion. Don’t just go for what’s popular right now though- make sure you choose something that reflects your personality, after all styles come and go but you're going to have to live with whatever you choose for the foreseeable future. Mediocrity is Awesome InspirationThe first time anyone tries something different it can be a little... underwhelming, and there’s lots of really good ideas out there that are, in fact, poorly executed. If you’re not really an ideas person it’s much easier to improve on someone else's good idea and it’s not really “stealing” as there’s few original ideas under the sun anyway. Alternatively- if you are a creative kind of person, make things that you wish existed (and make them well, if you don’t want someone a year from now making the same idea, only better.) Takeaway Tip: Before you begin your car project have a firm idea of what this car is going to be and what it will mean to you. Do your research, come up with some ideas and then talk to as many people as possible to get feedback- even if it's not what you want to hear. No one, not even great artists, exist in a vacuum and there's no need to hole yourself up in your garage reinventing the wheel- take other people's ideas and improve on them or adapt them to suit your style. 2) Will it be Practical?So you’ve decided on your “aesthetic” next step is figuring out how this car is going to fit with your lifestyle. Sadly ascetics and practicality are usually in direct opposition; you’re trading the way something looks for the way it suits your needs. Those rat look seats with the springs sticking out might be a bargain and look cool- but do you actually want to sit on them? People with kids ALWAYS want modern seat belts (unless they hate their children) whereas people without kids are happy to stick with the old belts for the sake of originality. And do I even need to mention the impracticality of a lowered car? The constant fear of speed bumps and curbs can take some of the fun out of driving. A very original car is nice to have but we’ve moved on in terms of technology. You can get after-market features such as power steering and interior heaters added for comfort and ease- but they will look out of place. As anyone who's seen power-steering fitted on a VW Splitscreen or VW Bay window knows, you're left with an unsightly motor sticking off the side of the steering column that's very difficult to hide- but hey, look at you smashing those three point turns one-handed! The Takeaway: What looks good is often not practical and vice versa- you need to decide what trade-offs you’re willing to make for the perfect car. Also be warned that there's a certain brand of die-hard classic car enthusiasts who are of the firm opinion that people concerned with safety and comfort should not be allowed to drive classic cars anyway (I was once screamed at and abruptly hung up on by a camper bed salesman for asking, on behalf of a customer, about safety features). These people will not look kindly on your pimp mobile with power-steering and Subaru engine conversion. 3) What About Parts and Materials?With aesthetics and practicality down we're getting on to the trickier stuff now. If you’re doing the work yourself you’ll be sourcing your own materials which is a massive job in itself, before any of the real fun begins! And even if you’re getting someone else to do the work for you, you’ll definitely need to discuss material options with them. In our experience people painfully underestimate how much parts and materials cost (actually, in our experience people underestimate how much stuff costs in general, but that’s a different conversation) and with big projects we usually don’t end up charging any extra for parts to help keep costs down for the customer. Practically every aspect of your classic car restoration- from the interior to the engine- has multiple options for parts and materials. This sheer volume of choice can be overwhelming, especially if you've never taken on a project like this before. Most importantly, you need to make sure you’re not being overcharged for sub-standard parts. So how would you do that? You flip a 50p coin once and it's heads. You flip three more 50p coins and three more times they all land on heads. Based on your experiment would you surmise that any 50p coin when flipped will always land on heads? Would you bet your life on it? Probably not. If you kept going with the experiment and flipped 1000 50p coins, the chances that you'd always get heads would be much smaller, practically impossible, in fact. What was the point in that you're wondering? Well stay with me, because this same principle can be applied to finding good quality car parts. Mechanics and other professionals who work on cars daily have a much wider experience, seeing which brand of parts wear out quickly and which ones last a reasonable amount of time (they have flipped the 50p coin 1000 times) whereas enthusiasts that like to work on their own cars can only recommend parts based on their individual experience (they have only flipped the 50p coin a few times). So to know what a good make of part is you need to talk to a professional mechanic/ welder/ auto electrician/ car upholsterer- preferably a specialist that has plenty of experience working on your type of car and using a variety of different brands of parts and materials. For instance, when it comes to welding there’s lots of different quality reproduction panels on the market- cheap ones are often thinner and not as well pressed, or are “over” panels which are made slightly too big (presumably so you can weld them over the top of rotten panels?!) You’ll spend more time trying to make these rubbish panels fit properly, so from our point of view in the shop it works out better to get the more expensive, higher quality panels as cheaper ones take longer to fit- so will cost the same to the customer in the end. However, when it comes to upholstery the opposite is true- as a luxury material you might think leather is the best option, but it’s actually harder to clean than vinyl and a lot more expensive. You’ll also get charged more because it’s harder to work with and you need specialist equipment- a walking foot sewing machine- to sew it, so vinyl is a cheaper and better option. Annoyingly, most specialist companies offer both rubbish quality and good quality parts for sale on their websites- making it far too tempting for enthusiasts to buy the cheaper option only to be dismayed when it doesn’t fit right, or breaks after only a couple of months. Seeing a customer rock up with a boot full of budget parts and a smug “try-and-rip-me-off-now-mate” attitude is the stuff of every mechanic’s nightmares- especially when you have to try and explain to these customers that all the parts they've just spent a small fortune on are no good. The other times where we've seen people waste money on parts and materials is when they discover a specialist website that sells everything for their car project... not realising that these parts fit numerous cars and can be bought cheaper elsewhere. Like a lot cheaper. I'm not taking about saving a few pennies here, I've seen parts on specialist websites for double and triple the price of other general car suppliers. Takeaway tip: Choosing the right parts and material for your car project is integral to its success, which is why you need expert guidance if you don't want to waste your money. If you don’t have enough confidence in your mechanic’s/ welder’s/ upholsterer’s expertise to let them advise you on what parts and materials to buy- just don’t use them! End of. Implying someone is untrustworthy by insisting on buying everything yourself (and only trusting the advice of the company that sold you the parts!) but still expecting that same someone to do the work on your project car will sour the working relationship before it’s even begun. 4) Any Must-Have Features?Finally, if there’s something you’ve always wanted on your project car that you’re not willing to compromise on, such as:

You need to take that into consideration right from the beginning for your budget. Use that feature as the focal point for the entire project, building everything else around it. The last thing you'd want to do is run out of money and have to do without it as you'll never be completely happy with the project if this ends up being the case. Takeaway Tip: Plan ahead! Make a list of essential features you want the car to have in order of priority (but you can only do so much, so give yourself a break and don't make it too long) so you don't run out of time or money to do the things you really want. Comments are closed.

|

watch our new youtube channelOur blog delivers brutally honest advice for the “rotbox” in your life with the aim of raising the standard of car projects everywhere.

Practical, direct, actionable ideas and zero bull. Read on. About

|

AboutWe're a dedicated, independent fabrication company based in rural North Yorkshire that specialises in light general fabrication work including CNC plasma cutting and CNC sheet metal bending.

|