|

As part of the resto work on our VW T25 I needed to make a new front cab headlining. The old one was a bit dried out, battered and yellowed with age so I decided a replacement was in order. The only problem was I had a job to find anyone selling them, so that meant getting the sewing machine out and doing it myself which I've turned into another Car DIY tutorial. Getting Started: You Will Need

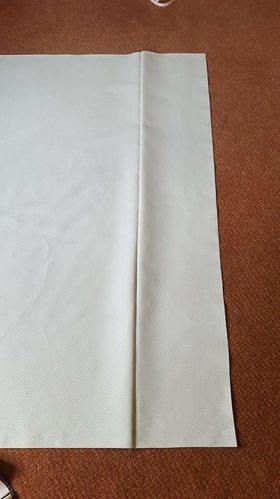

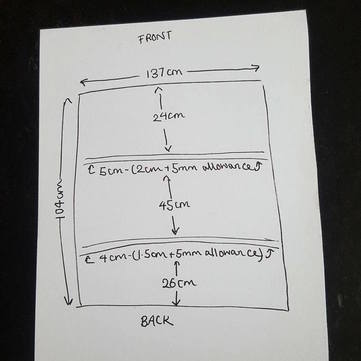

3 IMPORTANT RULES FOR DIY CAR UPHOLSTERY: SEWING A VW T25 FRONT CAB HEADLINING YOURSELF1) MEASURE MEASURE MEASURE Don't underestimate the power of your tape measure. I measured every bit of that old headlining about a million times before I cut anything to make sure it was accurate, I drew a diagram with all the measurements on it and everything. If you don't have the old headlining or it's not in any shape to use just try measuring the inside of the van instead, or use my measurements on the diagram below. 2) DRAW DRAW DRAW I used a black biro pen (just on the back part that wasn't on show) to mark out all the lines I wanted to sew as well as the centre of the fabric- which turned out to be really useful when it came to fitting the headlining too. 3) GO AS SLOWLY AS YOU NEED TO It took me way longer than it should have to do all that measuring and sew two lines on a small piece of fabric- but it's better than rushing it, making a mistake and wasting fabric. With the white perforated vinyl I was using once you puncture it with the needle it makes a permenant hole so you can't really unpick it again as it makes a mess, not to mention weakens the fabric. Basic Steps to Sewing Your Own Replacement Front Cab Headlining for a T25

10 Steps to Fitting a New Front Cab Headlining in your VW T25 Camper

And That's It!Well there you go, making and fitting your own headlining for a VW T25 is pretty simple to do, so have a try at some DIY upholstery on your camper van- or pop down to see us and we'll whip you one up. Liked this? Check out these...Comments are closed.

|

watch our new youtube channelOur blog delivers brutally honest advice for the “rotbox” in your life with the aim of raising the standard of car projects everywhere.

Practical, direct, actionable ideas and zero bull. Read on. About

|

AboutWe're a dedicated, independent fabrication company based in rural North Yorkshire that specialises in light general fabrication work including CNC plasma cutting and CNC sheet metal bending.

|