|

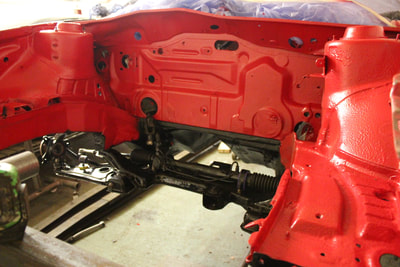

No one enjoys having to fork out for welding repairs on their vehicle, or repairs of any kind on their car for that matter. But welding repairs are particularly bad because, unlike changing out a broken part for a new one, there’s no quick fix for a rotten chassis. For a proper repair that metal has to be completely chopped out and replaced with fresh steel. Lots of otherwise perfectly good, reliable cars get sent to the scrapyard every year for being completely rotten to the point of being dangerous- much to the annoyance of their owners, who never even knew there was a problem until it was far too late to do anything about it. I just had a quick search on the internet to find out “how many cars fail MOT for welding” every year and, although I didn’t find that answer, what I did find was quite illuminating. Hundreds of angry and confused people on forums absolutely incensed at the cost of welding their car which has failed an MOT for “excessive corrosion”. “How can it be so expensive?! Surely, I’m being ripped off??” Is the general gist of every new post, with the odd retired welder or mechanic appearing to comment that “erm, actually yeah decent welding is expensive.” Even with classic car restorations it’s a similar story. Despite dealing with people who have a passion for and interest in cars, this kind of work is still a hard sell because welding is probably the least sexy part of restoring a car. No one is drooling over the thought of those rotten sills getting fixed up in quite the same way people fantasise about their engine upgrades or custom paint jobs. (The exception to this is, of course, custom metal fabrications like tubbed wheel arches and tubular front ends- but that’s a pretty niche area.) The only people who are genuinely getting excited about welding up rotten cars are welders themselves, while everyone else is just annoyed at this seemingly unnecessary expense. So, with all this in mind, let’s get right down to it and discuss the five different ways you can save money on vehicle welding repairs. 1) Do the Grunt Work Yourself- Strip Down Your Car Welding a car is a massive fire hazard because it’s full of flammable stuff like carpets, underseal and fuel tanks which can catch fire and even (fun fact!) explode. It’s not always necessary to remove the interior and fuel tank from a car before welding it, depending on whereabouts the area of bodywork that needs welding is, but if it is needed you’ll be doing everyone a huge favour by getting it out yourself. Welders want to weld, not spend a day removing and then another day refitting your car interior. And then they have to find somewhere clean to store all that mass of interior (not a particularly easy task in any workshop) and probably valet it once it’s refitted in the car, adding a fair chunk of hours onto your labour bill. Get that interior out yourself and store it away safely before you bring it to the workshop and I guarantee your welder will love you for it. DO NOT CHOP OUT THE ROT YOURSELFDon’t get ahead of yourself there though. Removing the interior is a fairly easy but time-consuming task. Chopping the rot out is, by comparison, a pretty quick job that if you decide to take on yourself under the impression of saving money will actually achieve the opposite. Why? By chopping out the rot you actually make the job harder for the welder because they need to see what the area looks like to begin with so they can copy it and make it look factory. Taking over a half-done welding job is a lot harder than doing it from the beginning. 2) Avoid the Need for Welding in the First Place- Rustproof Your Car If you’re reading this article it’s probably too late for your car now to which I can only say: sorry about that. BUT for the next time: RUSTPROOF YOUR CAR. Avoid the need to get your car welded by protecting it from the elements. We put salt on the roads in the UK and that combined with wet weather means cars driving around unprotected are gonna get rusty and rotten- especially on the underneath like the sills, chassis and arches, which are the most common areas for cars to fail an MOT on. I’ve written a DIY guide on how to completely rustproof your car at home, or just take it to a garage that offers a rustproofing service (our rustproofing service starts from £100 for small cars). The extra cost at this point will save you money on expensive welding repairs in the future. 3) Forget Welding- Buy Replacement Panels Instead Chopping out rot and welding in fresh steel is labour intensive, involves a high level of skill to make it look good and, as mentioned before, can be dangerous because of the fire hazard welding poses meaning you often need a second person on the job just to fire watch- all reasons which make it expensive, with many garages having a different, higher hourly labour rate for welding (we don’t). So, another way to fix your car that doesn’t involve welding is to just replace all those rotten panels with new or good second-hand ones. This isn’t always possible if the part of the car that needs welding doesn’t bolt off the car easily and will involve a bit of effort finding good quality replacement panels, but it usually works out cheaper than welding repairs, which is why we always recommend this wherever possible to our customers. When buying panels you need to find something that’s free of rust. Surface rust is ok if the panel has been bare metalled but check carefully for bubbling in the seams, especially along the bottom edge where water would usually sit. Try to avoid reproduction panels as they tend to be made from thinner gauge steel and will rot out quickly, therefore not saving you any money. Genuine, new old stock panels are the holy grail of the car restoration world which, if you’re lucky enough to come across, will always be a worthwhile investment. 4) Skill Trade- Got a useful skill to offer up? Trade Work Like for Like Got something useful to offer besides money? Trade your own awesome skills for welding on your car. Small business owners often have to take on the work of what is usually at the very least three, differently trained, full time employees- cleaner, accountant, marketing director as well as whatever their actual business is (car welding, as the case is here) so extra help with anything is always appreciated. Bonus points if you can somehow help them save money too. As I wrote in an earlier article: You do actually need to be already skilled at something useful for a skills trade to work well or at least be determined to make yourself useful (this is called showing initiative and is a very important life skill!) And also: Be specific in what you're going to offer. Don't say you'll do "anything" because then that other person needs to apply mental effort to think of something for you to do, which is extra work for them not to mention irritating and the complete opposite of making their life easier. So they'll say no. You want to make it as easy for them to say yes as possible. You can read more about skills trading here. Should you use the guy down the road who welds for beer money? I’m (obviously) really biased here, but there are a few good reasons not to use someone who's dirt cheap and/or not a professional welder. Firstly, there are very few people in the world willing to do an excellent job for not much money or free. People who are good at what they do respect themselves enough to charge a fair price for their work, everyone needs to make a living, etc, etc... In our experience, friends who offer to do things as favours (for free) are the worst at actually getting round to doing those jobs or will soon be after you asking for a (usually) much bigger favour. And, as my quick perusal of those forum pages showed, good work ain’t cheap and cheap work ain’t good. An individual who paid £75 for MOT welding repairs last year was quoted £400 to get the same bit re-done this year- most likely what it should have cost in the first place to get it fixed properly. Internet horror stories aside though, in the three years we’ve been in business we’ve seen more than our fair share of dodgy and downright dangerous welding repairs that people have paid next to nothing for including, but not exclusively:

Not to mention all the generally rubbish welding repairs that hadn’t penetrated properly so the patches could be torn straight off with our bare hands- which wouldn’t really stand up to much in an accident. Finally, that person doing welding on the side for cheap does not have insurance and, like I said earlier, welding is a massive fire hazard. 5) Learn How to Weld Haven’t got a useful skill? It’s time to learn one. Obviously, I’m talking long game here, as learning to weld takes time so is not a quick fix for your rotten car right now but will be a worthwhile skill to have for the future. It takes 10,000 hours to become an expert in anything or so the theory goes so put some time aside and get practicing. Aren’t we afraid of the competition? Not really. Matt’s an obsessive perfectionist who’s been welding part-time since he was 16 and full time for the last three years since we opened the workshop so I’d say he’s passed that 10,000 mark a few miles back. On top of that, it’s really hard to find a decent welder in North Yorkshire so if you’re also an obsessive perfectionist and can learn how to weld to a good standard please get in contact, we’d love to meet you. In Conclusion So there are my five best tips to save money on welding, with a few pointers on how NOT to try and save money on welding. Just remember, when it comes to welding on cars cheap (usually)=bad. Put in a little effort by either removing your interior, sourcing some decent second-hand panels or skills trading work like for like to cut down the cost of welding repairs on your car. Looking towards the future, always rustproof your car as soon as you get it to stop the rot from setting in and, if you feel like learning a new skill, have a go at welding yourself so you’re prepared the next time you have a vehicle that needs repairing.

Comments are closed.

|

watch our new youtube channelOur blog delivers brutally honest advice for the “rotbox” in your life with the aim of raising the standard of car projects everywhere.

Practical, direct, actionable ideas and zero bull. Read on. About

|

AboutWe're a dedicated, independent fabrication company based in rural North Yorkshire that specialises in light general fabrication work including CNC plasma cutting and CNC sheet metal bending.

|